Oliomio Form

Installation for cold oil extraction by centrifugation. Ideal for producers who want to process olives immediately after harvesting to obtain high-quality extra virgin oil. It is a piece of equipment designed for small and medium-sized productions that provides a high degree of flexibility when carrying out the oil extraction process. Equipment consisting of a mill, mixing system and decanter. Oliomio Sintesi allows processing between 200 kg and 1000 kg of olives per hour, depending on the option chosen. Si necesita más información sobre este producto, rellene el siguiente formulario y contactaremos con usted. Gracias.

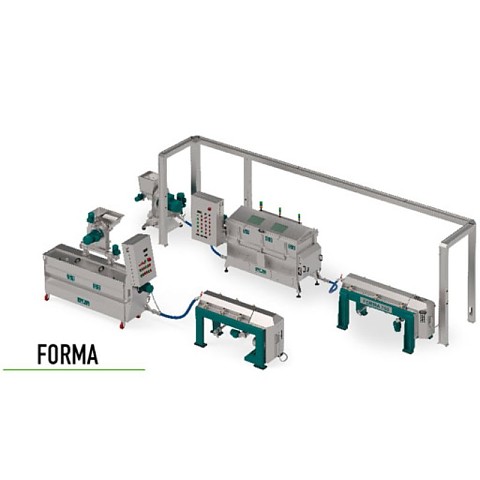

There are different configuration possibilities of the Oliomio Forma equipment that can be studied depending on the space available for its location and the existing production needs. Thus allowing olive processing of 200 kg, 250 kg, 350 kg, 500 kg, 750 kg and 1000 kg per hour, depending on the option chosen.

- Equipment consisting of a mill, mixing system and decanter.

- The mill is equipped with knives, a fixed screen with a diameter of 250 mm up to the 500 kg processing model and a diameter of 350 mm for higher models with 6.5 mm holes with a cleaner.

- Linear mixers with a single agitator and a single control temperature. FQ= mill and board on board.

- Heating jacket with recirculation and valves for external management.

- Paste inlet pumps to the decanter with variable speed.

- Flow meter for dosing water extraction.

- Decanter with two outlets with 2.0 auger.

- Possibility of processing continuously or discontinuously.

- Electrical panel equipped with thermal protection and made to work continuously and discontinuously with stainless steel cables and channels for various connections.

- Controls the temperature of the paste in: the mill, the mixers, the outlet of the paste to the decanter and the outlet of the oil from the decanter.

- The standard voltage of electric motors is 380V, 50 Hz.

- Vacuum pump, Optional.

The Forma installation has been designed to carry out preparations in standard batches in a continuous or discontinuous cycle. In the 2GL models the mill is mounted on the mixer with separate discharge into buckets 1 or 2 and in the 3GL and 4GL models the mill is separate. The management of oxygen at the mill entrance characterizes the production and constitutes a very important factor that allows the formation of lipoxygenase. Beating is done in closed mixers to prevent oxidation in the paste and ensure effective temperature control. The inlet of the paste is managed in the 2GL models by a worm screw and in the 3GL and 4GL models by means of a pump with solenoid valve, and the outlet is managed by means of an elliptical piston pump mounted on each mixer. The horizontal decanter that separates the liquid from the solid has been designed to obtain maximum quality performance; The 2.0 worm screw has been made to obtain the cleanest product possible without adding water. During extraction there is no increase in temperature. In conclusion, it can be stated that Forma facilities allow the extraction of a great product, in all phases of production, that makes the difference.